In the evolution of architectural design, thermal comfort has always been a core metric for measuring quality of life. From open fires to cast-iron radiators and now to radiant heating systems, the un...

READ MOREThe Evolution of Home Comfort: Why Underfloor Heating Panels are Redefining Modern Living

In the evolution of architectural design, thermal comfort has always been a core metric for measuring quality of life. From open fires to cast-iron radiators and now to radiant heating systems, the understanding of "warmth" has shifted from simply raising room temperature to a comprehensive management of heat distribution, air quality, and energy efficiency. In this transformation, the Underfloor Heating Panel serves as the physical foundation of radiant heating, playing a critical role in redefining comfort. Unlike traditional convection systems, the Underfloor Heating Panel creates an environment where thermal energy is managed with surgical precision, ensuring that heat is directed exactly where it is needed most.

The core philosophy behind the Underfloor Heating Panel is the elimination of thermal waste. In conventional buildings, heat tends to pool at the ceiling, a phenomenon known as stratification. This results in significant energy loss through the roof and upper wall sections. By utilizing an Underfloor Heating Panel, the thermal energy is released at the lowest point of the room, allowing the natural law of physics to distribute warmth in a way that aligns with human biology. This shift in HVAC paradigms is not just about comfort; it is a fundamental move toward sustainable building practices.

From Convection to Radiation: The Scientific Evolution of Heating

Traditional heating systems, such as radiators or air conditioners, rely primarily on air convection. This method works by heating local air, causing it to rise while cool air sinks, creating a cycle. However, convection heating has inherent flaws: uneven temperature distribution. Hot air accumulates at the ceiling while the living area (the floor) remains cool. This causes a "hot head, cold feet" sensation and moves dust and allergens, affecting air quality. Furthermore, the constant movement of air can lead to dry skin and respiratory irritation, which is particularly problematic in colder climates where indoor heating is used for several months consecutively.

In contrast, radiant heating systems built on the Underfloor Heating Panel follow the principle of thermal radiation. The entire floor becomes a massive heat-emitting surface, with heat traveling as far-infrared rays directly to people and objects. This reduces air disturbance and creates an ideal temperature field that matches human physiological needs. By utilizing an Underfloor Heating Panel, the thermal energy is stored and released evenly, preventing the rapid fluctuations often associated with traditional forced-air systems. The result is a silent, invisible, and incredibly stable heating experience that traditional radiators simply cannot match.

Defining the Underfloor Heating Panel and Functional Integration

Commonly perceived as just a layer under the pipes, modern HVAC engineering views the Underfloor Heating Panel as a composite structure integrating insulation, fixation, heat conduction, and protection. It does not just carry the heating elements; it determines the direction of heat flow—ensuring heat radiates upward into the room rather than dissipating into the building foundation. High-quality panels use high-density foam (like EPS or XPS) as a substrate, locking in heat through closed-cell microstructures. This insulation layer is vital because, without a proper Underfloor Heating Panel, up to 20% of the generated heat could be lost to the ground below or into the structural slab.

The integration of these functions within a single Underfloor Heating Panel simplifies the supply chain and installation process. Instead of sourcing separate insulation boards, pipe clips, and vapor barriers, a modular Underfloor Heating Panel provides a multi-functional solution that reduces human error during installation. This integration is the key to achieving the tight tolerances required by high-performance energy certificates and modern building codes.

Core Parameter Comparison: Radiant Heating vs. Traditional Convection

| Heat Transfer Mode | 80% Convection, 20% Radiation | 90% Radiation, 10% Convection |

| Water Temperature | High (65°C - 80°C) | Low (35°C - 45°C) |

| Vertical Gradient | Hot at top, cold at bottom | Hot at bottom, cool at top |

| Air Velocity | High (0.2 - 0.5 m/s) | Extremely Low (less than 0.1 m/s) |

| Energy Efficiency | Medium | High (15%-30% savings) |

| System Lifespan | 15 - 20 Years | 50+ Years (for the Panel and Pipe) |

Vertical Temperature Profile: Pursuing Ergonomic Perfection

The human body perceives temperature locally. Scientific studies show that the most comfortable state is when the feet are slightly warmer than the head. Underfloor Heating Panels allow for a temperature of 25°C - 28°C at the feet and 18°C - 20°C at the head. Because the heat source is directly underfoot, the temperature decays slowly as it rises, perfectly matching the human physiological ideal curve. This creates an environment where the perceived warmth is higher even if the actual thermostat setting is lower, leading to significant energy savings over time. Furthermore, the lack of drafts caused by an Underfloor Heating Panel system means that the body loses less heat through evaporation, further enhancing the sensation of coziness.

Releasing Space Aesthetics and Design Freedom

Beyond thermal advantages, the Underfloor Heating Panel contributes significantly to modern interior design. With the rise of minimalism and open-plan living, bulky radiators are often a visual distraction. Invisible heating hides all elements beneath the floor finish, freeing up walls for floor-to-ceiling windows, custom furniture, or art. Users can plan layouts freely without worrying about furniture blocking heat output. The structural integrity of a high-quality Underfloor Heating Panel also means that heavy interior elements can be placed without fear of damaging the underlying system, provided the compressive strength of the panel is correctly specified for the load.

Anatomy of an Underfloor Heating Panel: Materials and Engineering

If design is the soul, then materials and structure are the torso of the Underfloor Heating Panel. In complex flooring environments, the panel must withstand static and dynamic loads while maintaining physical stability over decades. The engineering behind the Underfloor Heating Panel focuses on maximizing thermal resistance (R-value) while maintaining a low profile to satisfy modern architectural constraints. Every millimeter of thickness in an Underfloor Heating Panel must be justified by its performance, as floor height is often a premium in urban developments.

Core Materials: The EPS vs. XPS Rivalry

Mainstream Underfloor Heating Panel substrates consist of polystyrene foams: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). These materials are chosen for their excellent balance of lightweight properties and high compressive strength. However, the manufacturing process for each leads to distinct performance profiles that dictate where each type of Underfloor Heating Panel should be deployed.

EPS (Expanded Polystyrene): Created by expanding beads in a mold. It offers good breathability and cost-effectiveness. It is easily molded into complex "studded" shapes, making it the most common material for an Underfloor Heating Panel used in residential "wet" installations. High-density EPS provides sufficient support for standard domestic loads while maintaining an affordable price point.

XPS (Extruded Polystyrene): Manufactured via a continuous extrusion process, forming a closed-cell honeycomb structure. This gives XPS natural advantages in compressive strength and moisture resistance, making it the ideal Underfloor Heating Panel substrate for high-load environments or areas where moisture ingress is a concern, such as basements or industrial floors. The closed-cell nature of an XPS-based Underfloor Heating Panel also prevents the absorption of liquid screed, ensuring the insulation properties remain intact throughout the life of the building.

Physical Parameter Comparison: EPS vs. XPS

| Thermal Conductivity | 0.033 - 0.038 W/mK | 0.028 - 0.032 W/mK |

| Compressive Strength | 200 - 300 kPa | 300 - 700+ kPa |

| Water Absorption | less than 2.0% | less than 0.5% |

| Max Operating Temp | Approx. 75°C | Approx. 75°C |

| Recyclability | 100% Recyclable | 100% Recyclable |

Heat Reflection and Aluminum Foil Integration

High-end Underfloor Heating Panels often integrate a layer of high-performance aluminum foil. This metal film performs two tasks: Thermal Radiation Reflection bounces heat upward, reducing downward loss; Lateral Heat Distribution uses aluminum's high conductivity to spread heat from pipe areas to gaps, eliminating "cold spots" on the floor. This integration within the Underfloor Heating Panel is especially crucial in "dry" systems where there is no concrete screed to help distribute the thermal energy. Without the foil or plate on the Underfloor Heating Panel, the floor would exhibit a "striped" heat pattern, which can lead to discomfort and uneven expansion of floor finishes.

Structural Engineering: Studs vs. Pre-grooved Designs

Studded/Castellated Designs: Support fastener-free installation. Pipes click directly between studs without the need for plastic ties, reducing the risk of puncturing moisture barriers. The Underfloor Heating Panel studs are engineered to hold pipes securely at specific intervals (usually 50mm increments), ensuring precise heat calculation. These studs also act as structural pillars that help distribute the weight of the screed above.

Pre-grooved Designs: Typically used in dry systems. Pipes are fully embedded within the Underfloor Heating Panel, minimizing height and preventing noise caused by thermal expansion. These panels often come with pre-bonded aluminum plates to maximize the radiant surface area. The precision of the grooves in an Underfloor Heating Panel is vital for ensuring that the pipe remains flush with the surface, allowing the floor finish to lay perfectly flat.

Compressive Strength and Structural Integrity

Standards require an Underfloor Heating Panel to reach a compressive stress of at least 200 kPa at 10% deformation. This ensures every square meter can support approximately 20 tons, sustaining heavy furniture like pianos without structural damage. When selecting an Underfloor Heating Panel, the long-term creep resistance is just as important as the initial strength to prevent floor sinking over a 50-year lifespan. For high-traffic areas or commercial spaces, specialized Underfloor Heating Panels with ratings of 500 kPa or higher are often required to prevent fatigue in the floor layers.

Categorizing Underfloor Heating Panels by Application

The choice of an Underfloor Heating Panel is largely dictated by the type of floor construction—whether it is a new build or a renovation project. Each scenario presents unique challenges regarding weight, height, and drying times.

Wet System Panels: The High Thermal Inertia Standard

In wet systems, the Underfloor Heating Panel is buried within concrete or screed. These panels feature high studs and a density between 25 - 35 kg/m3. The screed acts as a heat storage medium, providing extremely stable heat release even after the system is turned off. The Underfloor Heating Panel in this scenario acts as a thermal break between the structural slab and the heated screed. Because wet systems are typically used in new construction, the Underfloor Heating Panel must be robust enough to handle the rigorous activity of a construction site.

Dry System Panels: Ideal for Renovations

Dry panels require no concrete; pipes are laid directly into pre-grooved panels. These Underfloor Heating Panels are typically only 15mm - 20mm thick. The system heats up 3-4 times faster than wet systems and is lightweight, perfect for timber-framed buildings or second-floor installations. Because the Underfloor Heating Panel is the primary layer, it must be exceptionally rigid. Dry systems are increasingly popular for "retrofit" applications where homeowners want to add radiant heating without the mess and weight of concrete. In these cases, the Underfloor Heating Panel is often glued directly to the existing subfloor.

System Comparison: Wet Panels vs. Dry Panels

| Build Height | 70mm - 110mm | 15mm - 30mm |

| Pipe Diameter | 16mm / 20mm | 10mm / 12mm / 15mm |

| Static Load | 120 - 180 kg/m2 | 5 - 15 kg/m2 |

| Heat-up Time | 2 - 4 Hours | 30 - 60 Minutes |

| Structural Weight | Heavy | Ultra-Light |

Electric Underfloor Heating Panels

In bathrooms or kitchens, electric Underfloor Heating Panels offer flexibility. They feature thinner, denser grooves for heating cables or pre-attached mats. These panels often have high R-values to prevent electricity wastage, paired with enhanced fire retardant ratings. An Underfloor Heating Panel designed for electric systems often features a decoupling membrane functionality to prevent tile cracks caused by the rapid temperature changes inherent in electric cables.

Thermodynamic Performance and Energy Management

Efficiency in a radiant system is not just about the heat source but about how the Underfloor Heating Panel manages that energy. Thermodynamics dictates that heat will flow to the coldest area; the panel ensures that area is the room above, not the soil below.

The Decisive Influence of R-Value

The core metric of an Underfloor Heating Panel is its R-value (Thermal Resistance). Thicker panels with lower conductivity have higher R-values. For ground floors in contact with soil, a minimum R-value of 1.25 - 1.50 m2K/W is recommended to prevent the ground from absorbing heat. The Underfloor Heating Panel essentially acts as a one-way valve for thermal energy. If the R-value is too low, the energy consumption of the system can skyrocket, as the boiler or heat pump works to heat the entire earth beneath the house.

Response Speed and Thermal Inertia

In dry systems, the Underfloor Heating Panel allows for a temperature rise of 1°C per 10 minutes. High-quality panels force over 95% of heat to radiate upward, ensuring the energy paid for actually enters the living space. Low-quality Underfloor Heating Panels with poor insulation properties can increase energy consumption by up to 25% due to downward heat loss. The choice between high or low thermal inertia depends on lifestyle: a Underfloor Heating Panel with high inertia (wet) is better for 24/7 occupancy, while low inertia (dry) is ideal for rooms used only in the evenings.

Temperature Uniformity and Lateral Heat Transfer

High-end pre-grooved Underfloor Heating Panels feature aluminum heat-diffusing fins or full plates. Aluminum's conductivity is 200 times that of concrete. This ensures the temperature difference between any two points on the floor is kept within 2°C, preventing "hot strips" and ensuring the Underfloor Heating Panel provides a seamless blanket of warmth. This is critical for preventing the uneven expansion and contraction of delicate floor finishes like engineered wood or large-format porcelain tiles.

Energy Management Standards

| Downward Heat Loss | Energy Waste % | Less than 10% |

| Surface Temp Gradient | Comfort Level | Less than 2°C |

| Long-term Stability | Aging Risk | Drift less than 5% over 50 years |

| Flame Retardancy | Safety | B1/B2 Rating |

Professional Installation Workflow and Techniques

The longevity of a system is heavily dependent on the installation precision of the Underfloor Heating Panel. A system is only as good as its weakest link, and in radiant flooring, that link is often the interface between the panel and the subfloor.

Subfloor Preparation and Inspection

The flatness of the base floor must be within ±3mm/2m. Significant errors cause voids under the Underfloor Heating Panel, leading to physical fatigue and potentially causing the pipe to rub against the panel, creating noise. A 0.2mm PE moisture barrier is recommended before laying panels on ground floors to protect the Underfloor Heating Panel from rising dampness. If the subfloor is particularly uneven, a self-leveling compound must be applied before the Underfloor Heating Panel is installed.

Modular Layout and Interlocking Systems

Modern panels use interlocking designs to ensure a continuous thermal barrier. Installation follows a "staggered" pattern to distribute pressure at joints and increase structural rigidity of the heating floor. Each Underfloor Heating Panel must be firmly seated against its neighbor to prevent screed from leaking underneath, which can cause "panel float." In dry systems, the Underfloor Heating Panel must be secured with appropriate adhesives or mechanical fixings to prevent movement that could cause floor squeaks later.

Pipe Layout and Embedding Technology

The studs on an Underfloor Heating Panel preset standard spacings like 150mm. Guide grooves must accommodate the minimum bend radius (usually 5 times the pipe diameter) to prevent long-term stress leaks. The Underfloor Heating Panel studs are also designed to protect the pipe from being stepped on during the screeding process. Proper pipe layout within the Underfloor Heating Panel also ensures that the return and flow pipes are balanced, preventing one side of the room from being warmer than the other.

Edge Compensation and Expansion Joints

At the junction of the Underfloor Heating Panel and the wall, an 8mm - 10mm edge insulation strip must be installed to absorb horizontal pressure from thermal expansion and prevent wall cracking. This perimeter strip works in tandem with the Underfloor Heating Panel to create a fully floating, thermally isolated floor slab. Without this strip, the expansion of the floor could push against the walls, causing structural damage or buckling of the floor finish.

Installation Comparison: Traditional vs. Modular

| Positioning Accuracy | Manual, high error | Physical locking, error less than 2mm |

| Installation Speed | 5-8 mins/sqm | 1-2 mins/sqm |

| Moisture Barrier Risk | High (punctures) | Zero (no penetration) |

| Labor Intensity | High | Low |

Compatibility: Matching Panels with Floor Coverings

An Underfloor Heating Panel must be chosen based on the final floor finish to ensure both thermal efficiency and structural stability. The relationship between the Underfloor Heating Panel and the floor finish is one of the most critical aspects of system design.

Tiles and Stone: Underfloor Heating Panels must have extreme compressive strength (XPS is preferred) to support heavy adhesive and stone layers without shifting. Any microscopic movement in the Underfloor Heating Panel would cause grout lines to crack and tiles to delaminate.

Wood Flooring: The surface temperature must be strictly controlled, typically not exceeding 27°C, requiring the Underfloor Heating Panel to provide even heat distribution via aluminum spreaders. This prevents hot spots that warp timber. It is also essential to ensure the Underfloor Heating Panel is perfectly dry before wood is laid to prevent moisture absorption by the flooring.

Micro-cement and LVT: These thin finishes require high-density Underfloor Heating Panels with self-locking structures to ensure absolute flatness. Because these finishes provide no structural support themselves, the Underfloor Heating Panel must act as the rigid foundation for the entire floor.

Advanced Science: Acoustic and Environmental Attributes

The Underfloor Heating Panel offers benefits beyond temperature, acting as a crucial component in building acoustics and healthy living environments.

Acoustic Dampening: Impact Sound Improvement

The foam structure of an Underfloor Heating Panel acts as a natural acoustic buffer. High-quality 30mm panels provide an impact sound reduction of 18dB - 25dB, significantly improving peace in multi-story homes by decoupling the floor finish from the structure. This "acoustic separation" is often a requirement in building codes for apartment blocks. By choosing a high-performance Underfloor Heating Panel, developers can meet both heating and acoustic requirements with a single product.

IAQ and Thermal Stability

Quality Underfloor Heating Panels pass TVOC testing. Under continuous heat, they do not produce formaldehyde or odors and must meet B1 or B2 fire retardant standards for safety. A non-toxic Underfloor Heating Panel is essential for maintaining a healthy indoor environment, especially for inhabitants with allergies or asthma. Furthermore, unlike carpeted floors or radiators, an Underfloor Heating Panel system does not harbor dust mites or trap pet dander, leading to cleaner indoor air.

Identifying High-Performance Underfloor Heating Panels

| Density | Tight surface, no powdering | Loose, fragile edges |

| Flexibility | Tough, doesn't snap easily | Brittle, cracks under pressure |

| Locking Precision | Tight joints, hard to pull | Loose joints, visible gaps |

| Fire Test | Self-extinguishes instantly | Continues to burn with smoke |

| Certifications | CE, ISO, EPD | None or faked |

FAQ:

Why is the density of the Underfloor Heating Panel so important?

Density is directly linked to compressive strength. Low density leads to irreversible deformation under heavy furniture, causing tile cracks or floor noise. Choose Underfloor Heating Panels with a density of 30-35kg/m3 or higher for residential use. A high-density Underfloor Heating Panel ensures that the system maintains its shape and performance for the entire lifespan of the building.

Is a thicker panel always better?

Not necessarily. Thickness depends on insulation needs. Ground floors require at least 40mm-50mm to satisfy building regulations, while intermediate floors only need 20mm-30mm to block downward heat transfer without wasting ceiling height. The efficiency of an Underfloor Heating Panel is a balance of thickness and material conductivity. In many cases, a 30mm XPS Underfloor Heating Panel will outperform a 50mm low-density EPS panel.

What happens if the "studs" are broken during construction?

A few broken studs won't ruin the heating, but it increases the risk of pipes shifting during the screeding or flooring process, leading to uneven heat. It is best to replace any Underfloor Heating Panel that has significant structural damage before the final floor is laid. Broken studs can also create "air pockets" in the screed, which act as insulators and reduce the heat output in that specific area.

Does the Underfloor Heating Panel cause odors when heated?

No. High-quality Underfloor Heating Panels are made from inert materials like EPS or XPS that do not release VOCs or formaldehyde even when subjected to long-term heating at 50°C. Always look for IAQ-certified products. If you detect an odor, it is more likely coming from the floor adhesive or the floor finish itself rather than the Underfloor Heating Panel.

Can the panel mold or rot if there is a leak?

No. EPS and XPS are synthetic materials that do not provide nutrients for bacteria or mold. Their low water absorption (less than 0.5%) ensures structural stability even in damp conditions. However, the presence of water around an Underfloor Heating Panel will drastically reduce its R-value, so leaks should be fixed immediately. Moisture trapped beneath an Underfloor Heating Panel can also lead to issues with the subfloor if it is made of timber.

Underfloor Heating Panels represent the precision era of building heating. From material selection to thermodynamic control and standardized installation, every aspect serves to create a comfortable, energy-efficient environment. Selecting the right Underfloor Heating Panel is the fundamental guarantee of a high-quality modern lifestyle. By understanding the technical parameters of the Underfloor Heating Panel, homeowners and developers can ensure a system that is both durable and incredibly efficient, providing silent warmth for generations to come.

Discover the timeless beauty and craftsmanship of Evergrowing through our featured products.

-

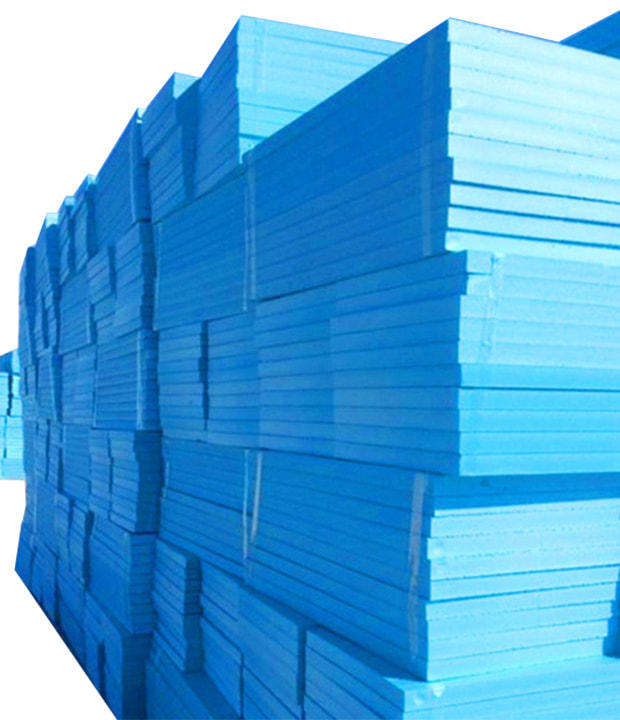

XPS underfloor heating panel

XPS underfloor heating panel

-

EPS underfloor heating panel

EPS underfloor heating panel

-

EPS Crown Molding T-06

EPS Crown Molding T-06

-

EPS Crown Molding T-04

EPS Crown Molding T-04

-

EPS Crown Molding T-02

EPS Crown Molding T-02

-

EPS Crown Molding

EPS Crown Molding

-

EPS Crown Molding T-18

EPS Crown Molding T-18

-

EPS Crown Molding T-20

EPS Crown Molding T-20

-

EPS Crown Molding B-06 B-08 B-10 B-12

EPS Crown Molding B-06 B-08 B-10 B-12

-

EPS Crown Molding B-22 B-20 B-24 B-18

EPS Crown Molding B-22 B-20 B-24 B-18

-

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

-

EPS Crown Molding B-30 B-28 B-34 B-32

EPS Crown Molding B-30 B-28 B-34 B-32

-

EPS Crown Molding B-42 B-40 B-38 B-36

EPS Crown Molding B-42 B-40 B-38 B-36

-

EPS Crown Molding B-60 B-44 B-58

EPS Crown Molding B-60 B-44 B-58

-

EPS Crown Molding B-56

EPS Crown Molding B-56

English

English 中文简体

中文简体 Español

Español