In the evolution of architectural design, thermal comfort has always been a core metric for measuring quality of life. From open fires to cast-iron radiators and now to radiant heating systems, the un...

READ MOREHow do underfloor heating panels compare in terms of thermal efficiency and comfort to traditional radiators?

Introduction to Underfloor Heating Panels and Traditional Radiators

Underfloor heating panels and traditional radiators represent two common approaches to indoor heating. While traditional radiators rely on convective heat transfer to warm air in a room, underfloor heating panels provide radiant heat from the floor surface. Users often compare these systems based on thermal efficiency, comfort, energy consumption, and distribution of warmth throughout living spaces.

Principle of Heat Distribution in Underfloor Heating

Underfloor heating panels distribute heat evenly across the floor surface. Warmth rises gradually, creating a uniform temperature gradient from the floor to the ceiling. This radiant heat minimizes cold spots in a room and can enhance overall comfort. By directly warming the floor, it reduces the need for high air temperatures to achieve a comfortable environment.

Principle of Heat Distribution in Traditional Radiators

Traditional radiators typically use convective heat transfer. Water or steam circulates through the radiator, warming the surrounding air. Heated air rises and cooler air moves toward the radiator, forming convective currents. This can result in uneven heat distribution, with warmer areas near the radiator and cooler zones further away, potentially reducing perceived comfort.

Thermal Efficiency Comparison

Underfloor heating panels generally operate at lower water temperatures compared to radiators, which can improve energy efficiency. Lower operating temperatures reduce heat loss in pipe networks and allow boilers or heat pumps to work more efficiently. In contrast, traditional radiators often require higher water temperatures to achieve the same level of warmth, potentially increasing energy consumption.

Comfort Perception and Surface Temperature

Comfort is influenced not only by air temperature but also by surface temperature. Underfloor heating panels provide warmth at the feet, contributing to a sensation of comfort even when ambient air temperature is slightly lower. Radiators, on the other hand, primarily heat the surrounding air, which may leave the floor cooler and require higher air temperatures to achieve the same comfort level.

Response Time and Heat Control

Underfloor heating panels typically have a slower response time due to the thermal mass of the floor. Once the panels are heated, they maintain warmth for an extended period, but initial heating may take longer. Traditional radiators respond more quickly to changes in water temperature or thermostat settings, allowing rapid adjustment of room temperature but potentially resulting in fluctuating comfort levels.

Distribution Uniformity

Underfloor heating provides a uniform distribution of heat across the room, which reduces cold spots and minimizes temperature stratification. Radiators can create localized warm zones near their placement while leaving distant areas cooler, which may lead to uneven comfort and the need for supplementary heating in certain parts of the room.

Impact on Air Movement and Indoor Air Quality

Underfloor heating panels rely primarily on radiant heat, producing minimal air movement. This can help reduce the circulation of dust and allergens, contributing to a more stable indoor air environment. Traditional radiators induce convective currents, which may increase dust movement and slightly impact indoor air quality, especially in rooms with high dust or allergen levels.

Energy Consumption and Operating Costs

Because underfloor heating panels operate efficiently at lower temperatures, they may reduce overall energy consumption compared to radiators, particularly when paired with high-efficiency boilers or heat pumps. Radiators operating at higher water temperatures can incur higher energy costs over time, although this depends on insulation, system design, and local climate conditions.

Compatibility with Renewable Energy Sources

Underfloor heating systems are often well-suited for renewable energy sources such as solar thermal systems or heat pumps. Their low-temperature operation aligns with the optimal efficiency of these systems. Traditional radiators may require retrofitting or larger heat output to maintain comfort when used with low-temperature heat sources, which can limit their compatibility with renewable systems.

Installation Considerations and Floor Integration

Underfloor heating requires integration with the floor structure, which can affect installation cost, height, and renovation planning. Radiators are typically easier to install in existing buildings and can be replaced or relocated with relative ease. Installation decisions may influence the long-term efficiency and comfort outcomes of each system.

Maintenance and Longevity

Underfloor heating panels are generally low-maintenance once installed, as most components are hidden beneath the floor. Radiators are accessible for inspection and maintenance but may require periodic bleeding, cleaning, or replacement of valves. Both systems have long operational lifespans if properly maintained.

Environmental Impact

By operating at lower temperatures and reducing energy demand, underfloor heating panels can contribute to lower carbon emissions when paired with efficient or renewable heat sources. Traditional radiators, depending on system efficiency and fuel type, may have a higher environmental footprint due to increased energy use.

Comparison Table: Underfloor Heating Panels vs Traditional Radiators

| Aspect | Underfloor Heating Panels | Traditional Radiators |

| Heat Distribution | Uniform radiant heat from floor to ceiling | Localized convective heat near radiator |

| Thermal Efficiency | Lower operating temperatures improve energy efficiency | Higher water temperatures required for comfort |

| Comfort | Warm floors enhance perceived comfort even at lower air temperatures | Air may feel warmer near radiator but cooler elsewhere |

| Response Time | Slower to heat initially, retains heat longer | Faster response to thermostat changes, but fluctuating comfort |

| Air Movement | Minimal, reduces dust circulation | Convective currents increase air movement |

| Compatibility with Low-Temperature Systems | Highly compatible with heat pumps and solar thermal systems | May require higher temperature sources for adequate comfort |

| Installation | Integrated into floor, may affect renovation planning | Mounted on walls, easier retrofit and replacement |

Discover the timeless beauty and craftsmanship of Evergrowing through our featured products.

-

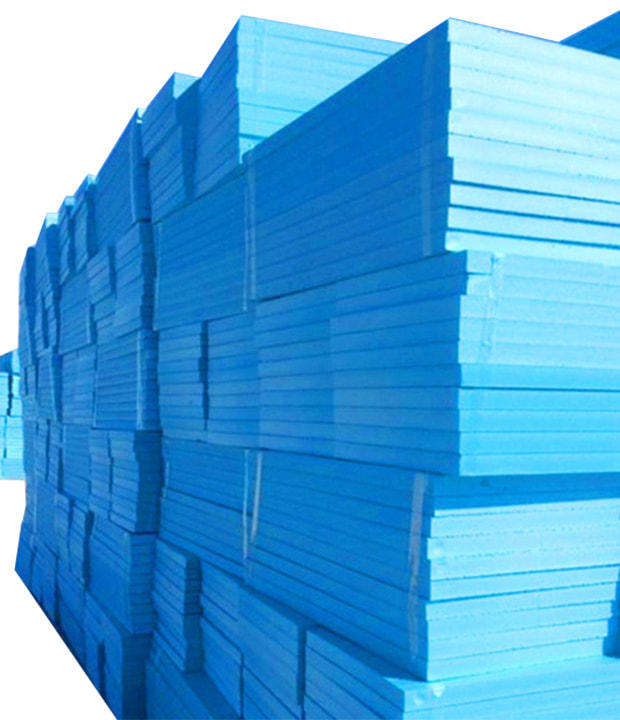

XPS underfloor heating panel

XPS underfloor heating panel

-

EPS underfloor heating panel

EPS underfloor heating panel

-

EPS Crown Molding T-06

EPS Crown Molding T-06

-

EPS Crown Molding T-04

EPS Crown Molding T-04

-

EPS Crown Molding T-02

EPS Crown Molding T-02

-

EPS Crown Molding

EPS Crown Molding

-

EPS Crown Molding T-18

EPS Crown Molding T-18

-

EPS Crown Molding T-20

EPS Crown Molding T-20

-

EPS Crown Molding B-06 B-08 B-10 B-12

EPS Crown Molding B-06 B-08 B-10 B-12

-

EPS Crown Molding B-22 B-20 B-24 B-18

EPS Crown Molding B-22 B-20 B-24 B-18

-

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

-

EPS Crown Molding B-30 B-28 B-34 B-32

EPS Crown Molding B-30 B-28 B-34 B-32

-

EPS Crown Molding B-42 B-40 B-38 B-36

EPS Crown Molding B-42 B-40 B-38 B-36

-

EPS Crown Molding B-60 B-44 B-58

EPS Crown Molding B-60 B-44 B-58

-

EPS Crown Molding B-56

EPS Crown Molding B-56

-

-

Introduction What is an EPS Ceiling Medallion? An EPS Ceiling Medallion refers to a decorative ceiling feature made from Expanded Polystyrene (EPS), a type of lightweight foam material. Commonly used ...

READ MORE -

What is a Ceiling Medallion, and How Does it Change the Visual Proportion of Interior Space? In the realm of high-end interior design, the ceiling is no longer an overlooked surface. Often referred to...

READ MORE

English

English 中文简体

中文简体 Español

Español