In the evolution of architectural design, thermal comfort has always been a core metric for measuring quality of life. From open fires to cast-iron radiators and now to radiant heating systems, the un...

READ MOREHow are the thermal conductivity, pressure resistance, and abrasion resistance of the underfloor heating panel?

Introduction to Underfloor Heating Panels

Underfloor heating panels are widely used in modern construction to provide efficient and even heating. These panels often integrate water or electric heating systems within a panelized structure, allowing heat to be transferred through the floor surface. Their design and material composition, including polystyrene underfloor heating panels, influence performance factors such as thermal conductivity, pressure resistance, and abrasion resistance.

Thermal Conductivity of Underfloor Heating Panels

Thermal conductivity determines how efficiently heat moves through the panel from the heating source to the floor surface. High thermal conductivity ensures that warmth is distributed evenly and quickly across the room. Polystyrene underfloor heating panels typically combine polystyrene insulation with embedded heating elements or channels. The polystyrene provides thermal resistance to reduce heat loss downward, while the top layer or conductive inserts ensure heat moves efficiently to the floor surface. This balance allows energy-efficient operation while maintaining consistent surface temperatures.

Factors Affecting Thermal Conductivity

Several factors influence the thermal conductivity of underfloor heating panels. Material composition, thickness of insulation, and density of polystyrene layers all play a role. Thinner panels with higher-density conductive layers may transfer heat faster, while thicker insulation reduces downward heat loss but can slightly slow surface heating. Additionally, the type of heating medium—water, electricity, or a combination—affects how quickly heat is conducted through the panel.

Pressure Resistance of Underfloor Heating Panels

Pressure resistance is critical for underfloor heating panels since they must withstand the weight of flooring, furniture, and foot traffic. Panels are designed to distribute loads evenly and prevent deformation over time. Polystyrene underfloor heating panels are often reinforced with a rigid top layer or embedded mesh, improving their structural integrity. This ensures that the panels maintain their shape and alignment even under long-term use, avoiding uneven heating or damage to the heating system.

Design Considerations for Load-Bearing

Manufacturers typically consider maximum expected loads and provide safety margins to ensure panels do not crack or compress. The combination of polystyrene insulation and rigid top layers allows for both thermal efficiency and mechanical strength. Proper installation, including secure fixation and alignment, further enhances pressure resistance and overall durability.

Abrasion Resistance of Underfloor Heating Panels

Abrasion resistance determines how well panels withstand mechanical wear during installation and maintenance. Panels must resist scratches, scuffs, and surface damage that could compromise thermal transfer or insulation. Polystyrene underfloor heating panels are usually designed with a protective layer or coating to increase surface hardness. This layer reduces the likelihood of damage during handling or when the floor above is installed.

Impact of Surface Treatment on Abrasion Resistance

Surface treatments, such as laminated coatings or embedded mesh layers, improve the panel’s resistance to friction and mechanical wear. A panel with higher abrasion resistance retains its flatness and surface integrity over time, which is crucial for maintaining consistent heat transfer. Abrasion resistance also ensures that panels continue to perform efficiently even in high-traffic areas or under heavy flooring materials.

Balancing Thermal Conductivity, Pressure Resistance, and Abrasion Resistance

Effective underfloor heating panels strike a balance among thermal conductivity, pressure resistance, and abrasion resistance. High thermal conductivity ensures fast and even heat distribution, while adequate pressure resistance maintains structural stability. Abrasion resistance protects the panel during installation and from long-term wear. Polystyrene underfloor heating panels are often engineered to meet these three requirements simultaneously, combining insulating properties with reinforced surfaces.

Performance Table for Underfloor Heating Panels

| Property | Polystyrene Underfloor Heating Panels | Typical Requirements |

| Thermal Conductivity | Moderate to high, optimized with conductive layers | Efficient heat transfer to floor surface |

| Pressure Resistance | High, reinforced with rigid top layer or mesh | Withstands furniture weight and foot traffic |

| Abrasion Resistance | Enhanced with surface coating or laminated layer | Maintains panel integrity during installation and use |

Long-Term Performance Considerations

Over time, underfloor heating panels must retain their thermal, mechanical, and surface properties. Polystyrene underfloor heating panels are designed to resist deformation, wear, and thermal degradation under normal operating conditions. Proper installation, including avoiding excessive loads and following manufacturer guidelines, ensures that panels continue to function efficiently for many years. Regular inspections during flooring renovations or maintenance can help identify potential issues early, preserving both safety and thermal performance.

Integration with Heating Systems

The effectiveness of underfloor heating panels also depends on integration with the heating source. Panels must maintain close contact with pipes, cables, or conductive layers to ensure efficient heat transfer. Polystyrene panels with rigid and abrasion-resistant surfaces support proper alignment and secure integration, reducing the risk of air gaps or uneven heating. This integration ensures that the panel’s thermal conductivity is fully utilized while preserving structural stability.

Discover the timeless beauty and craftsmanship of Evergrowing through our featured products.

-

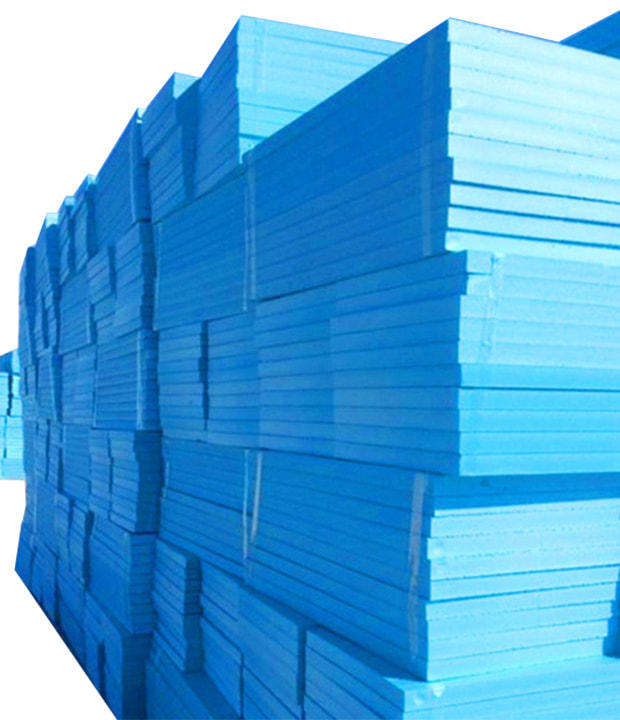

XPS underfloor heating panel

XPS underfloor heating panel

-

EPS underfloor heating panel

EPS underfloor heating panel

-

EPS Crown Molding T-06

EPS Crown Molding T-06

-

EPS Crown Molding T-04

EPS Crown Molding T-04

-

EPS Crown Molding T-02

EPS Crown Molding T-02

-

EPS Crown Molding

EPS Crown Molding

-

EPS Crown Molding T-18

EPS Crown Molding T-18

-

EPS Crown Molding T-20

EPS Crown Molding T-20

-

EPS Crown Molding B-06 B-08 B-10 B-12

EPS Crown Molding B-06 B-08 B-10 B-12

-

EPS Crown Molding B-22 B-20 B-24 B-18

EPS Crown Molding B-22 B-20 B-24 B-18

-

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

EPS Crown Molding B-26-1 B-26-2 B-26 B-16

-

EPS Crown Molding B-30 B-28 B-34 B-32

EPS Crown Molding B-30 B-28 B-34 B-32

-

EPS Crown Molding B-42 B-40 B-38 B-36

EPS Crown Molding B-42 B-40 B-38 B-36

-

EPS Crown Molding B-60 B-44 B-58

EPS Crown Molding B-60 B-44 B-58

-

EPS Crown Molding B-56

EPS Crown Molding B-56

-

-

Introduction What is an EPS Ceiling Medallion? An EPS Ceiling Medallion refers to a decorative ceiling feature made from Expanded Polystyrene (EPS), a type of lightweight foam material. Commonly used ...

READ MORE -

What is a Ceiling Medallion, and How Does it Change the Visual Proportion of Interior Space? In the realm of high-end interior design, the ceiling is no longer an overlooked surface. Often referred to...

READ MORE

English

English 中文简体

中文简体 Español

Español